Home > Products > Metal Roofing > Uni-Purlin & Metal Framing System

Uni-Purlin & Metal Framing System

The Channel Styles and Combinations You Need

INTRODUCTION

FEATURING THE UNIQUE UNI-PURLIN CONNECTION

- NO WELDING

- NO DRILLING

- 100% ADJUSTABLE

- 100% REUSABLE

SMALL C-PURLIN

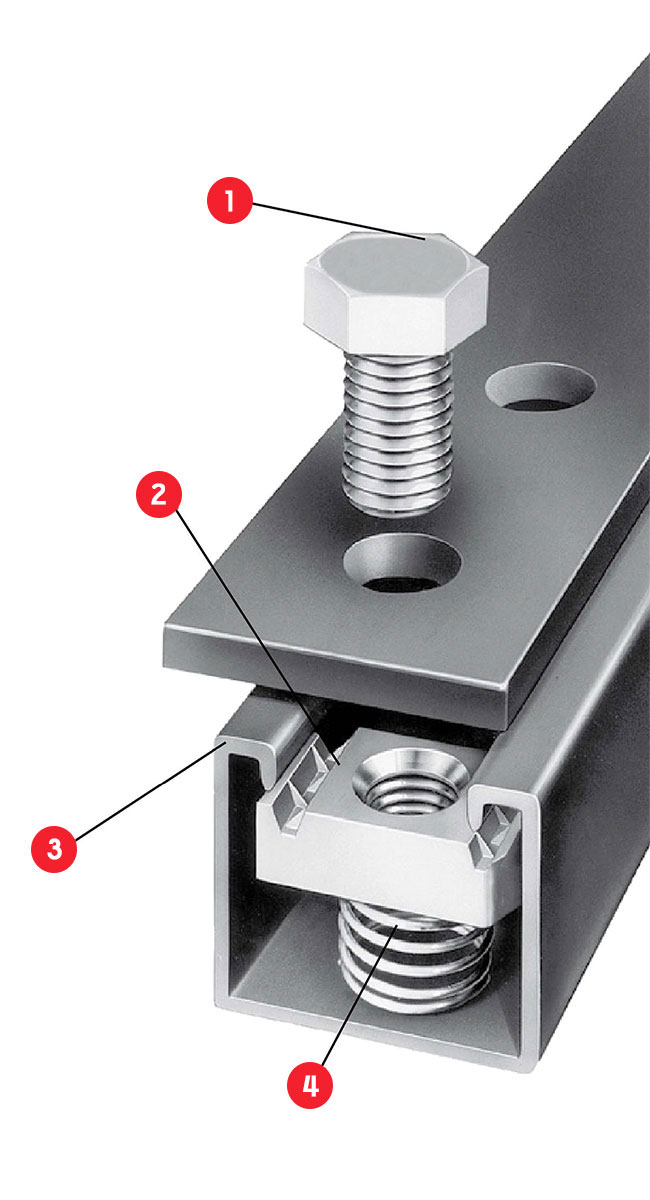

Hex-head bolt threads easily into a spring nut, connecting fitting to channel in quick one-hand operation.

Several channel sizes and hundreds of fittings give you engineered solutions to a virtually limitless variety of projects.

Nut teeth create a vice like grip,

tying sides together in a strong “box” configuration, when the nut is tightened against the in turned channel edges.

Spring allows precision placement anywhere along channel length then holds the nut in position while connection is completed.

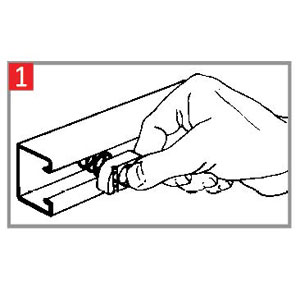

Insert the spring nut anywhere along the continious slotted channel. Rounded nut ends permit easy insertion.

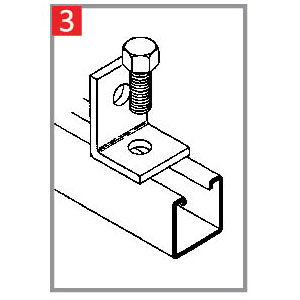

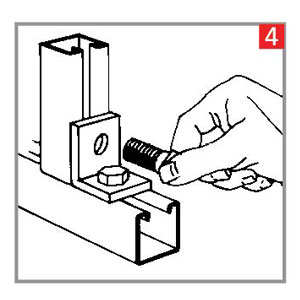

Addtional channel sections can now be bolted to the fitting already in place by following procedure described in step 1-3.

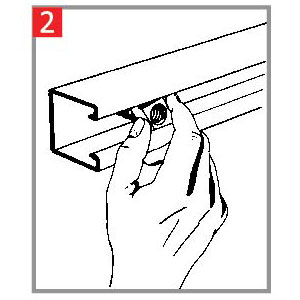

Insert bolt through fitting and into the spring nut.

Addtional channel sections can now be bolted to the fitting already in place by following procedure described in step 1-3.

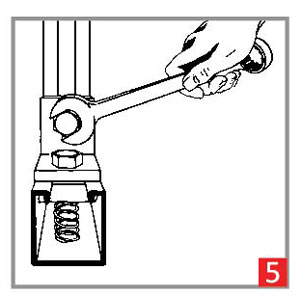

Tightening with a spanner locks the serrated teeth of the nut into the in-turned edges of the channel, forming a strong, vise-like connection.

THE CHANNEL STYLES YOU WANT AND THE COMBINATIONS YOU NEED

MATERIALS & FINISHES

MATERIALS

UNI-PURLIN

Uni-Purlin channels are steel from 1.6mm to 2.5mm, they are also available in Mild Steel, Pre-Galvanized. (G.I)

MILD STEEL CHANNELS

Mild Steel Channels are rolled using material formed by: JIS G3141 SPCC-SD equivalent to BS DIN EN 10130 and the minimum yield stress for our channel system is Ys=260N/mm2.

PRE-GALVANIZED CHANNELS

Pre-Galvanized Channels are rolled using material formed by: JIS G3302 equivalent to BS EN 10326 and the minimum yield stress for our channel system is Ys=260N/mm2.

Uni-Purlin fitting Comply with BS1449Part1:1983 or BS4360:1927 and are manufactured from hot-rolled, picked and oiled steel plates, strip or coil. They have a minimum yield stress of 170N/mm2 as specified in BS6946:1988.

Comply All fittings are manufactured from 6mm thick material unless specified otherwise. Uni-Purlin fitting can also be obtained in stainless steel.

Uni-Purlin Channel Nuts are made from high quality steel bar.

FINISHES

Hot-Dip Galvanized

Hot-dip galvanizing is a process where completely manufactured or roll-formed steel is chemically cleaned of all contaminants and then dipped in molten zinc. This will allow a coating consisting of iron/zinc-alloys which are usually over-coated with a layer of relatively pure zinc.

All hot-dip galvanizing is applied in accordance with ASTM A123:1989/BS EN ISO 1461:1999(E) which supersedes BS729:1971. The zinc coating thickness varies from 45μm (up to 2mm thick material for bolts and nuts) to 55μm (for at least 5mm thick material).

Pre-Galvanized (G.I)

Sheet metal (steel strip) is hot-dip galvanized in a continuous process which yields an even zinc coated sheet with a bright smooth metallic finish. Materials such as stell is galvanized prior to the manufacturing (roll-forming or press operations) of channels or fittings. All “pre-galvanized” steel used is in accordance with BS2989:1982 and usually grade Z275. Pre-Galvanized Hot Dipped Zinc Coated Steel JIS G3302.

Special Coating

Special Coating are also available upon request for all the channels and fittings: Epoxy Coated, Polyester Powder Coated and Thermoplastic Coated.

Plain (Mill Finish) Steel (Black)

Uni-Purlin channels and fittings are untreated and retain an oiled surface from the rolling or pressing process. Alternative steel grades and surface finishes are available upon request, but may be subject to minimum order quantities. Hot rolled steel P&O, JIS G3131 SPHC.

A WORLD OF SUPPORT FOR KEEPING PRODUCTION EFFICIENCY

TECHNICAL BRIEF

PRE-GALVANIZED STEEL

Pre-Galvanized steel (JIS G3302 SGHC/SGCC or BS EN 10142)

Pre-Galvanized steel is produced by running the steel sheet though a bath of molten zinc in a continuous process. The thickness of the zinc coating is less than that of hot dip galvanized products. This zinc coating is also interrupted at edges where the material is cut or punched. Some zinc is pushed over the cut edges during the cutting process to offer some protection. Products made from pre-galvanized materials are suitable for indoor use.

ELECTRO GALVANIZED STEEL (EG)

Electro galvanized steel (JIS G3313 SECC)

This is process whereby the steel is passed continuously through a series of plating cells where zinc is deposited onto the steel surface through the electrolysis process. The protective zinc coat thus obtained is relatively thinner than the material obtained by hot dip galvanizing. The finished products are usually recommended for indoor application in dry areas.

EPOXY POWDER COATED (EPC)

Powder coating is a process whereby the powdered resin and the steel product are electro are statically charged with opposing potential. The powder is sprayed onto the product and an even coat is formed. The coated product is then passed through an oven for baking to produce a glossy and hard finish. This coat can provide corrosion resistance against atmospheric moisture but not against more aggressive environment. It is recommended for indoor applications.

Powder coating can be applied to products with the following finish.

Mild steel mill finish

Hot dip galvanized finish

Pre-galvanized steel finish

Electro galvanized steel finish

HOT DIP GALVANIZED AFTER FABRICATION (HDG)

The most common selection for outdoor application is hot dip galvanized. After the cutting, bending and welding operation, the completed product goes through a series of treatment to remove grease and rust before being immersed completely into a bath of molten zinc. This complete immersion allows the zinc to bond onto every exposed surface of the product thereby affording exceptional protection, Defending on the environment, protection , Depending on the environment, protection can last for many years.

ZINC THICKNESS MEASUREMENT AFTER HOT DIP GALVANIZED

UNI-PURLIN SERIES

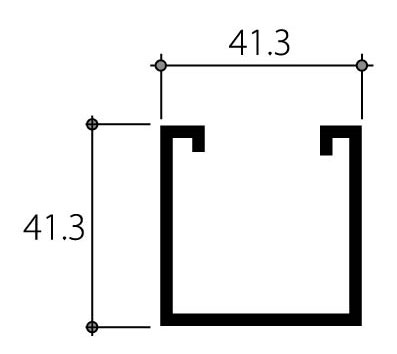

UP 41x41 Weight 2.7kg per metre

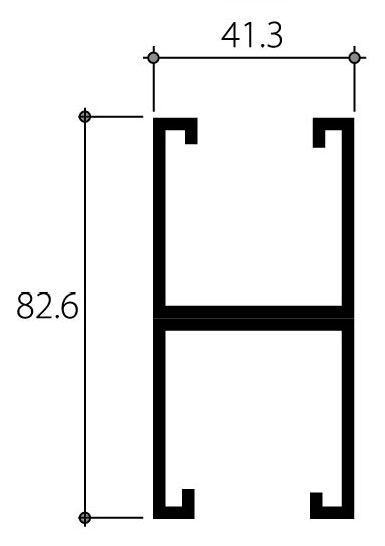

UP 41x82 Weight: 5.5kg per metre

UP 82x82 Weight: 11kg per metre

ELEMENT OF THE SECTION

UP 41X41 CHANNEL

BEAM LOADING DATA UP 41X41

COLUMN LOADING DATA UP 41X41

UP 41X82 COMBINATION CHANNEL

BEAM LOADING DATA UP 41X82

COLUMN LOADING DATA UP 41X82

UP 82X82 COMBINATION CHANNEL

BEAM LOADING DATA UP 82X82

COLUMN LOADING DATA UP 82X82

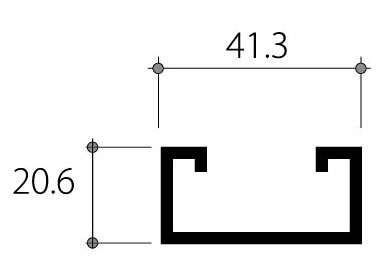

UP 20X41 SERIES

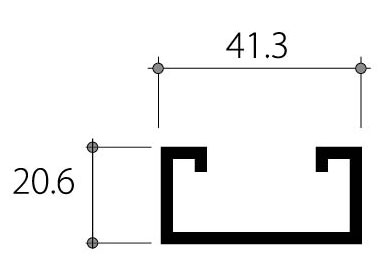

UP 20x41 Weight: 1.97kg per metre

UP 20x41 Double Weight: 3.91kg per metre

ELEMENT OF THE SECTION

UP 20X41 COMBINATION CHANNEL

BEAM LOADING DATA UP 20X41

COLUMN LOADING DATA UP 20X41

UP 20X41 COMBINATION CHANNEL

BEAM LOADING DATA UP 20X41 DOUBLE

COLUMN LOADING DATA UP 20X41 DOUBLE

UNI-PURLIN PIERCED CHANNEL

UP 41x41 with hole Weight: 2.5kg per metre

UP 20x41 with hole Weight: 1.65kg per metre

ELEMENT OF THE SECTION

UP 41X41 PIERCED CHANNEL

BEAM LOADING DATA UP 41X41 WITH HOLE

COLUMN LOADING DATA UP 41X41 WITH HOLE

UP 20X41 PIERCED CHANNEL

BEAM LOADING DATA UP 20X41 WITH HOLE

COLUMN LOADING DATA UP 20X41 WITH HOLE

CLOSURE STRIPS

UP 1184PVC

TYPICAL CHANNEL ACCESSORIES

UP 2335, UP 2540

DESIGN LOAD DATA

1. Both ends of beams supported

2. Loads are for: UP 41×41 2.5mm thick channels

M12 hardened spring nuts

3. Safety factor = 2 based on ultimate strength of connection

FLAT PLATE FITTINGS

UP 1064

UP 1065 Weight: 157g

UP 1036 Weight: 250g

UP 1066 Weight: 243g

UP 1031 Weight: 339g

UP 1067 Weight: 330g

UP 1028 Weight: 425g

ANGULAR FITTINGS

UP 1068 Weight: 159g

UP 1326 Weight: 1242g

UP 1749 Weight: 194g

UP 1026 Weight: 157g

UP 1325 Weight: 1327g

UP 1747 Weight: 263g

UP 110

UP 59

UP 1359 Weight: 458g

UP 689

UP 1713 Weight: 384g

UP 1033 Weight: 342g

UP 1331 Weight: 432g

UP 1186-135° Weight: 256g

UP 1035 Weight: 342g

UP 1332 Weight: 432g

UP 1546-45° Weight: 246g

UP 1034 Weight: 342g

"U" SHAPE FITTINGS

UP 1184PVC

TYPICAL CHANNEL ACCESSORIES

UP 2335, UP 2540

DESIGN LOAD DATA

1. Both ends of beams supported

2. Loads are for: UP 41×41 2.5mm thick channels

M12 hardened spring nuts

3. Safety factor = 2 based on ultimate strength of connection

ALL PRODUCTS

More Information

Please feel free to drop us a line and we will get back to you as soon as possible.